Traceability in Calibration: Why It Matters for Accurate Measurements

Calibration is essential in almost every facet of industrial processes today. The calibration process verifies test instrument accuracy by comparison with recognized standards, and measurement validity hinges on one crucial concept: traceability. Traceability adherence ensures a continuous link between your unit under test (UUT) and that standard. In this blog post, we examine traceability, exploring why it is necessary for achieving accurate measurement results.

WHAT IS TRACEABILITY

Traceability is documented evidence that confirms measurement accuracy through an unbroken chain of calibration events. When calibrating an instrument, accurate measurement results rely on this definitive link between the UUT’s indication and those established standards. For most industrial customers, an accredited calibration laboratory typically maintains these reference standards, possibly even climbing all the way to the National Institute of Standards and Technology (NIST). The accredited lab uses its standards, which are traceable to a higher-echelon lab, to calibrate field-level instruments. This traceable path ensures the calibrated instrument measurements are dependable.

WHY TRACEABILITY MATTERS

1. QUALITY ASSURANCE AND COMPLIANCE

Most industries perform some sort of measurement(s) to ensure product quality. This could be product sampling at various stages in the production process or end-of-line verification of the finished product. Quality assurance personnel rely on the traceability of their instruments to provide valid measurements, thus verifying in-specification results. The instruments used should be traceable to a higher-level standard, most often provided through a calibration service, either internal or external to the company. This traceability is critical in meeting regulatory requirements/standards, i.e., ISO standards or FDA regulations, as part of overall confirmation that the product meets specifications. Ensuring proper traceability demonstrates a commitment to compliance and overall product quality.

2. MEASUREMENT CONFIDENCE

Traceable measurements provide a higher confidence level and produce more consistent results. Users can trust that their data is reliable, thereby ensuring their product(s) meet specified tolerances. Proper traceability through established higher-level calibration standards will inherently result in nearly identical (nothing is ever perfect) results across different tools, laboratories, and even geographic locations. Traceability is a key factor in making informed decisions regarding production activities to ensure your company can achieve the best results.

3. LEGAL AND FINANCIAL IMPLICATIONS

A transparent audit trail can protect businesses from legal liability and regulatory issues. Proper traceability documentation provides objective evidence to any auditor that your program complies with regulatory or other requirements, thus reducing the risk of legal penalties and product recalls. Additionally, proper traceability mitigates risk, helping defend against financial audits, investigations, and other compliance-related actions. The same evidence of your commitment to compliance and quality mentioned above helps to safeguard against legal and economic setbacks

4. PROBLEM RESOLUTION

Another benefit of proper traceability is identifying and rectifying issues. Sound data provides the basis to delve into any measurement or calibration issue as it happens and pinpoint the concern to a product or process, taking swift action to resolve it. The confidence provided by traceability facilitates effective problem-solving strategies and prevents recurring issues. As a result, it reduces downtime and associated costs while enhancing product quality. Traceability ensures confidence in decisions and allows for continuous improvement.

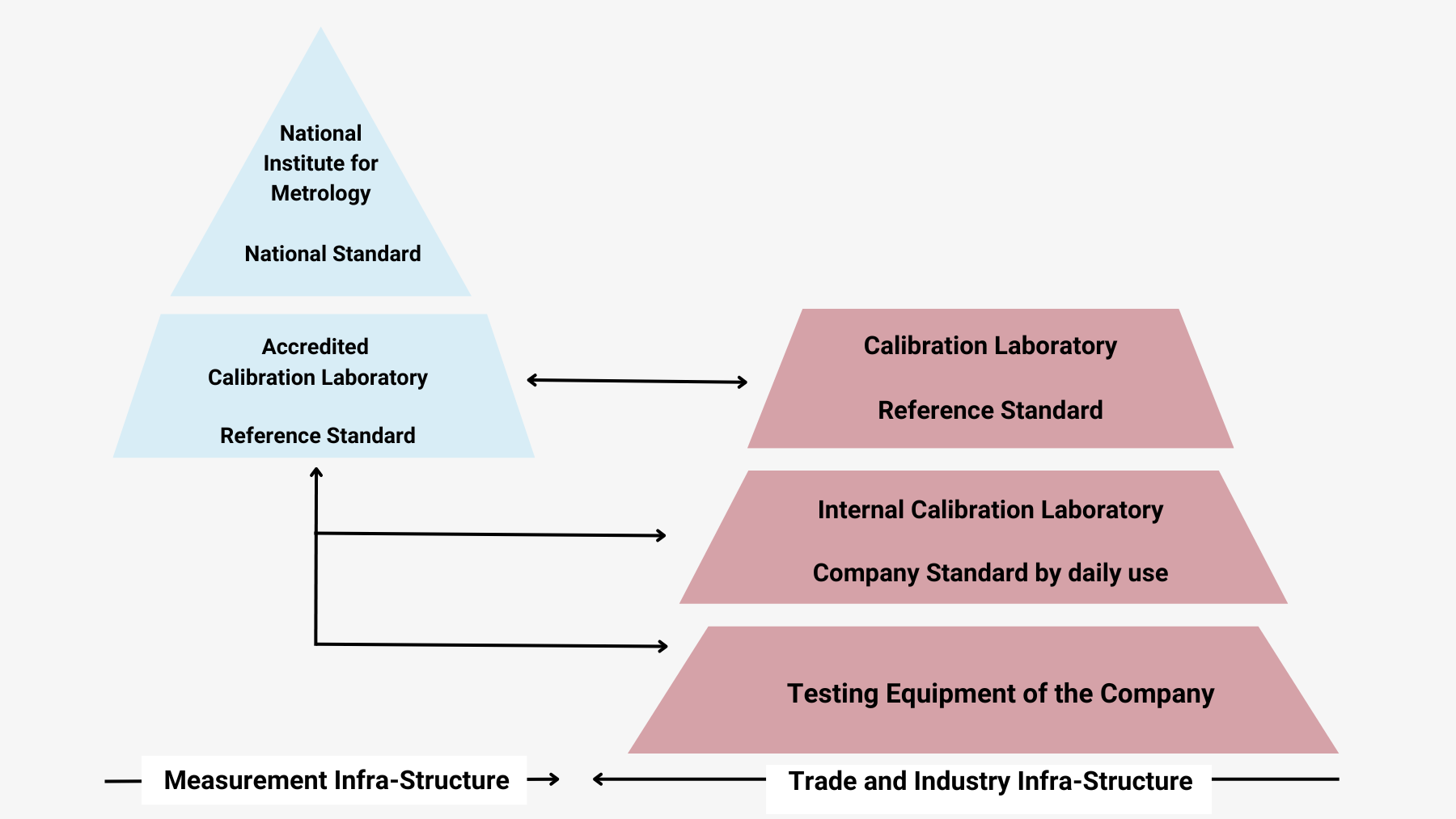

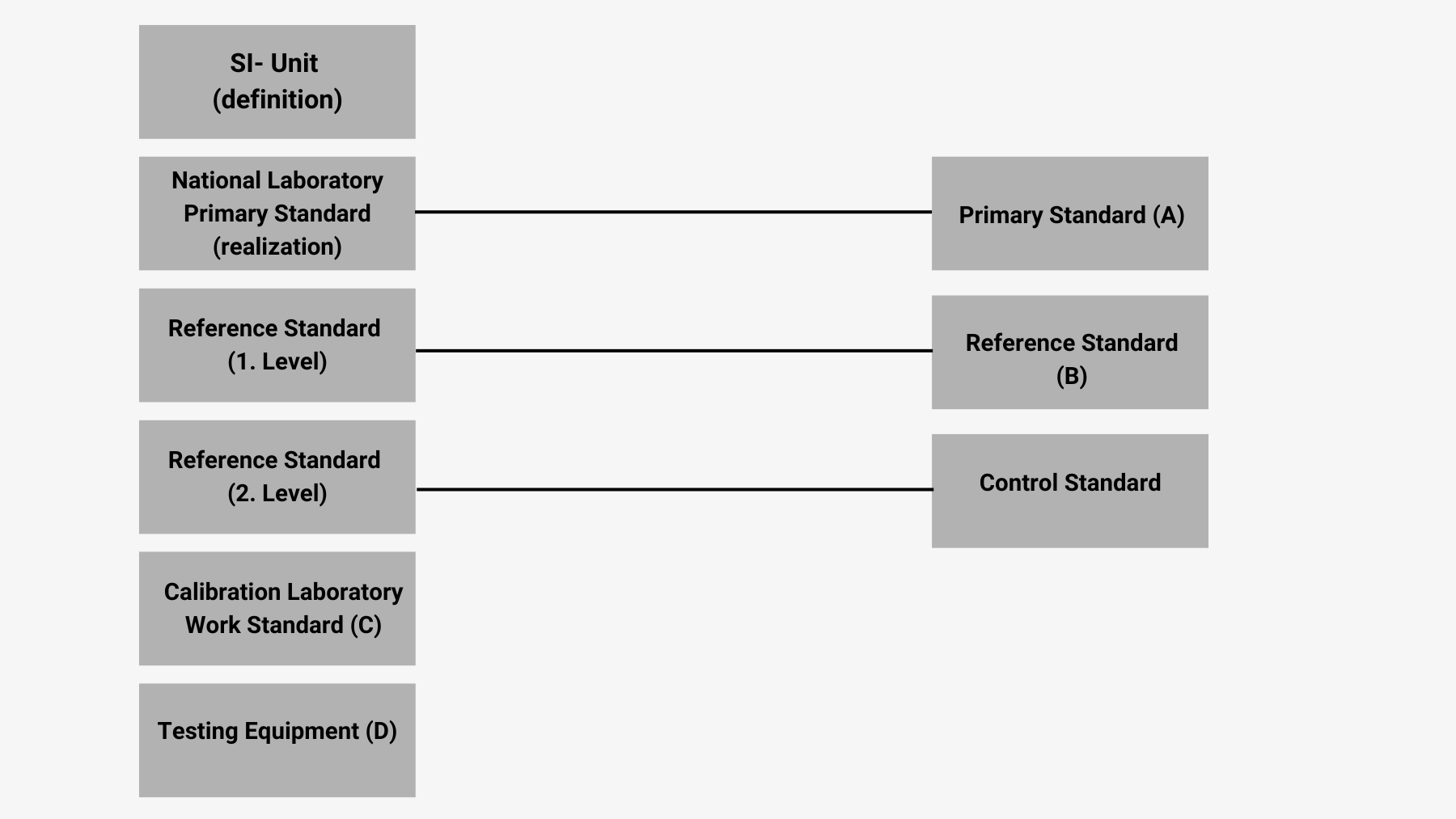

THE IMPORTANCE OF AN UNBROKEN CHAIN OF COMPARISONS

Traceability links the measurement to an internationally recognized standard through a documented series of comparisons. This “unbroken chain” ensures the integrity of measurement data, beginning with an initial comparison to the primary standard and then passing through one or more secondary standards to a working standard on the production floor.

Each step must be properly documented, ensuring each comparison is traceable to the reference standard. This unbroken chain of comparisons ensures reliability and accuracy at each step, with the ultimate PASS or FAIL result completely dependent upon the chain and proper documentation. Any flaw in the process could introduce errors that would affect down-the-line measurements, ultimately impacting quality control, compliance, and product reliability.

Figure 1: Calibration hierarchy from primary standard to test equipment

From 4.1 Traceability: An Unbroken Chain of Transfer Comparisons, by Gigahertz-Optik, n.d. (https://www.gigahertz-optik.com/en-us/service-and-support/knowledge-base/basics-light-measurement/detector-calib/traceability/). CC-BY 2.0.

Figure 2: Hierarchy of standards

From 4.1 Traceability: An Unbroken Chain of Transfer Comparisons, by Gigahertz-Optik, n.d. (https://www.gigahertz-optik.com/en-us/service-and-support/knowledge-base/basics-light-measurement/detector-calib/traceability/). CC-BY 2.0.

IMPLEMENTING TRACEABILITY IN CALIBRATION

1. SELECT AN ACCREDITED CALIBRATION LAB

Choose an accredited calibration laboratory that follows recognized standards and has a clear calibration traceability chain. A certified lab will perform calibrations according to established guidelines using traceable measurement standards. By selecting such a lab, you can be confident in the accuracy of your measurements and compliance with industry requirements.

2. DOCUMENT CALIBRATION PROCEDURES

Maintain detailed records of calibration procedures, including equipment used and methods employed. In many cases, the calibration provider maintains the critical components related to measurement traceability on the customer’s behalf. Still, organized records in your field-level facility enhance the overall process and can make regulatory compliance (and audits) less taxing. Calibrations performed by internal personnel levy the documentation burden on you since you are completing the work. Accurate records maintain the traceability chain regardless of source and ensure an auditable traceability chain for your measurements.

3. CALIBRATE INSTRUMENTS REGULARLY

Establish a calibration schedule for your equipment. Regular calibration can help organizations identify and resolve any measurement discrepancies as they occur. It makes you confident in the accuracy of your results. It helps mitigate any risks with faulty instruments, limiting the timeframe for any out-of-tolerance situation that could impact your end-of-line quality. Adhering to an established schedule contributes to the overall reliability of measurements and quality of your product.

4. MAINTAIN CALIBRATION CERTIFICATES

Keep calibration certificates from your accredited laboratory or any internal calibration records you produce. These certificates and records serve as objective evidence of maintenance performed and a tangible link between the measurements taken and recognized reference standards. Have these certificates organized and readily available to demonstrate your compliance.

5. IMPLEMENT A CALIBRATION MANAGEMENT SYSTEM

Use a calibration management system or software to track calibration schedules, maintain records, and generate certificates. Streamline the entire calibration process and ensure that your company maintains traceability. A centralized database provides easy access to historical data, saving time and effort to show your commitment to calibration traceability.

LAST WORDS

Accurate measurements and end product quality depend on traceability. It assures that your results are reliable and trustworthy. Understanding and implementing traceability in your calibration process is critical to overall measurement accuracy, quality, and compliance. In today’s environment, traceability is vital in driving progress and innovation. It guarantees measurements are not just accurate but also universally comparable and credible.

CONTACT US TODAY

At Master Gage & Tool Co., our commitment to precision and quality is unwavering. As a trusted gaging, inspection equipment, and specialty tooling distributor, we’ve served our valued customers since 1986. We take immense pride in our A2LA-accredited ISO 17025 calibration services.

When you partner with us, you’re not just investing in calibration; you’re investing in the success and reliability of your business. We invite you to reach out and discover how we can enhance your operations. Contact us today for a calibration quote, and let’s elevate your precision to new heights.

Our Danville Office: (434) 836-4243

Our Greenville Office: (864) 447-5100

Or use our online contact form.